What Does Hot Sprue Bushings Mean?

This has the benefit that no adjustments have to be made at the mold. hot sprue bushings. The resulting opening at the injected part from the gas intro, can be shut by postinjection.

Our team of Engineers and also Physicists will ensure that your copyright is realized with the critical cartridge heating unit. We listen, then act.

Tire mold and mildew layout at first begins with decision of the inflated dimensions of the needed tire size. By usage of inflated tire as well as development attributes of the tire, preliminary plyline and mold and mildew dimensions are computed (Figure 14.6). Once the mold and mildew boundary measurements, area of the plyline, and also walk size and deepness are recognized, the shapes of the tread, shoulder, sidewall, and bead elements can be developed.

Plyline limits. Figure 14.7. CADAM-developed mold and mildew tooth cavity. The key interest in developing a tire depends on the belt location, bead area, as well as belt and ply cord tension. As radial tires consist of several belts, these layups have to be seen as a package. The tightness of the radial tire belt package is a function of belt wire angles, wire gauge, belt scale, and also substance rigidity.

Some Known Facts About Hot Sprue Bushings.

As an empirical overview, a rise in the rigidity of the belt bundle, while keeping belt size, will certainly enhance walk put on performance. Number 14.8. (a) Normal four-belt layup for a truck tire. (b) Influence of Gough rigidity. The rigidity of a tire belt plan can be quantified by determination of the "Gough tightness" (S), which is an action of the in-plane flexing stiffness of the rigid belt cord, cable, as well as rubber substance laminate.

Elaborating, Gough identified that a basic beam of light model of tire building attributes can be used to predict relative step wear performance - hot sprue bushings. Making use of both shearing as well as flexing moments in the calculation, an empirical formula was derived defining the rigidity parameter S for a basic laminate( 14.2 )S =P/ d, where load, P, is the pressure related to the crown location layup or laminate to provide a deflection d.

Essentially, Eq. (14.3) can be simplified to a model containing a basic supported light beam of length L with elastic constants E and also G dispersed distance d by force P as( 14.4 )S= PL 3/48EI +2 PL/8AG, where A is the in-plane cross-sectional location to which the pressure P is applied, and I is the minute of inertia of the beam of light.

For a right/right/left/ ideal belt configuration, the belt angle (θ) of the second as well as 3rd belts was differed from 10 ° to 26 °. Computation of an optimum belt layup will certainly allow achievement of the called for Gough tightness. Structural mechanical estimations such as finite-element evaluation (FEA) are made use of to evaluate both the inflated and packed deflected shapes of a tire cross-section and the resulting stress-strain connections in the belt area.

The Only Guide for Hot Sprue Bushings

Figure 14.9 reveals a durable vehicle tire in the crammed and also unloaded states. The thickness of grids is created so regarding preserve the crucial features of the tire cross-section geometry while maintaining the total number of grid points. Figure 14.9. Finite-element framework of a heavy-duty truck tire. In an evaluation of the belt bundle, three conditions can be evaluated that enable computation of the series of stress power densities: inflated tire condition, packed tire condition 180 ° away from the footprint, and packed tire condition at the center of the footprint.

It shows that the stress power density in megapascals in an inflated tire resembles that in a lots tire 180 ° far from the impact. At the facility of the impact in a loaded problem, nonetheless, the pressure power thickness at the belt side has enhanced from the array 0.01-- 0.27 to 0.05-- 0.51 MPa.

Figure 14.10. Finite-element analysis of belt location showing strain energy density (in MPa). (a) Inflation. (b) Crammed 180 ° away from footprint. (c) Filled at facility of impact. Similar to the belt area of the tire, the grain region likewise offers itself to finite-element analysis. Switching grid information to the bead allows analysis of the ply end stress on rising cost of living as well as in a packed state as the tire makes a full change.

In today's world of injection molded items, decisions on mold layout and also building and construction are usually driven by preliminary price and also shipment. This fashion of mold purchase can position the molded part in a setting of not being at its long-lasting financial advantage for the firm producing the very first generation of parts, as well as not adding a fair share to the lower line profits for also short-run mold and mildews.

3 Easy Facts About Hot Sprue Bushings Described

On the other hand, a competitor with molds made for lasting components manufacturing, at the most effective ROI against the manufacturing run, will have a financial edge in rebidding, particularly if the very same treatments are reflective of the overall corporate expectation. Following are factors to take into consideration for both short-run as well as long-run injection formed plastic parts. hot sprue bushings.

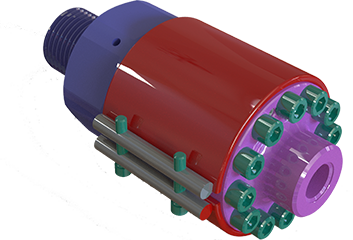

In the construction of a chilly bushing, single-cavity mold with edge-gating of the component, added mold and mildew size is called for to suit the jogger and also balanced out of the cavity from the sprue bushing. Properly designed systems will certainly provide a reduced profile hot jogger to move the material to the offset for edge-gating with the least rise in mold and mildew size.

By making use of a shutoff gateway to the parting line, much less material is required per shot, which saves power and minimizes scrap (sprues) or the percent of regrind utilized. The economic climates of using a hot runner to change mold countered are such that they need to be taken into consideration for all parts over 50g with a predicted manufacturing life over 150,000 components.

Using a sprue bushing to directly gate into a single-cavity mold and mildew supplies a number of benefits in the construction as well as operation of the mold and mildew over the cold runner type. The mold base dimension is only depending on the part requirements as well as will use the tiniest press required. When utilizing a chilly sprue bushing, a sprue is developed that should be gotten rid of, leaving a mark, which frequently need to be eliminated by second procedures if appearance or maximum height of the sprue rest are part considerations.

More Bonuses Read Full Article go to this web-site